Get in touch today

Finish Facades provides CWCT tested rainscreen systems for all types of high-end commercial and public sector cladding projects, so you can be sure that your rainscreen panels provide the quality necessary for their environment.

CWCT testing is a central part of our service, not only reflecting Finish Facades’ dedication to the quality of our products, but our commitment to our customers’ long-lasting satisfaction.

What is CWCT Testing?

The Centre for Window and Cladding Technology created a market independent standard for the structural integrity of building envelopes; within this, cladding can be CWCT tested to examine how it performs under typical climatic conditions.

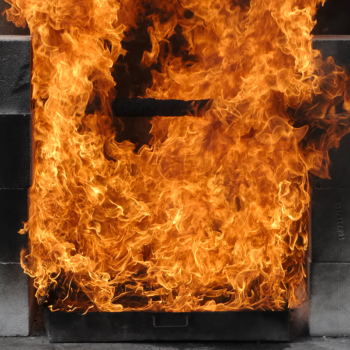

CWCT testing examines the design and performance integrity of a cladding system when exposed to water, air and solid object impact, the levels of which are typical for the environment.

The process of CWCT testing includes:

- Wind resistance - the panels are suction and pressure tested in a vacuum, pushing them against and away from the wall they are fixed to, before being tested for safety and security when under increasing pressure.

- Watertightness - water is sprayed continuously for 15 minutes, driven by simulated wind force in several directions. Sealed and open-jointed systems are then probed and tested for their water resistance.

- Impact resistance - impact resistance is tested by both a hard (solid steel ball) and soft (50kg leather bag of glass beads) body being swung at the wall. The structural performance of the wall is then tested.

CWCT Requirements

The panel must pass all three tests within the CWCT process in order for it to be classified as weathertight, and therefore CWCT certified.

Benefits of CWCT Testing

CWCT testing offers many benefits to architects, installers and clients.

- CWCT testing helps standardise rainscreen cladding for improved performance and durability of building envelopes.

- The testing proves the panels are able to withstand extreme weather conditions and don’t pose a hazard.

- CWCT tested panels further offer time and cost savings during construction and ongoing maintenance requirements.

Featured Case Study

(Heathrow) Premier Inn Reclad

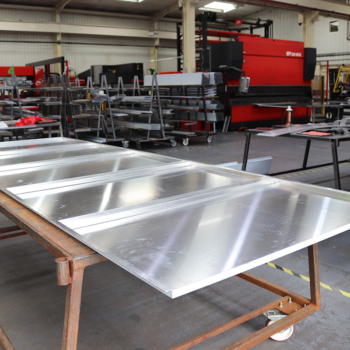

An ambition to deliver a transformational identity to the Premier Inn company, with the supply of.1.5Million reclad, 2,500sqm of 3mm solid Aluminium recess fix panels to replace current ACM panels.